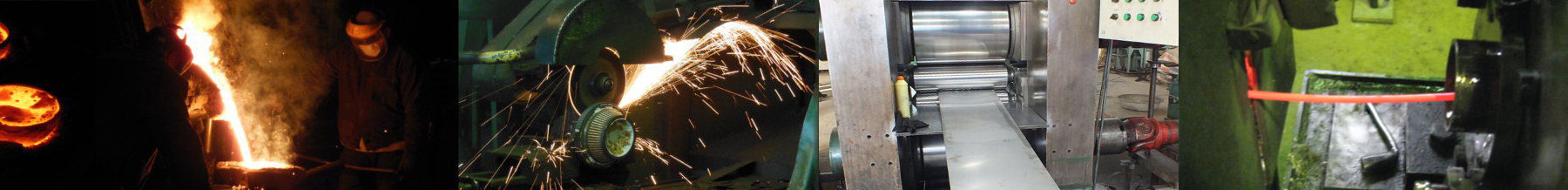

Your ideas - our job!

Tantalum. Tungsten. Chromium. Molybdenum

Round wire:

Diameter: 100 micron and more.

Delivery form: spool, coil.

Delivery min. lot: from 5 g in spool, from 1 kg in coil.

Rods, ingots, diameter - 2,0 - 200 mm.

Delivery min. lot - from 1 kg.

Quality certificate :

- SGS;

- VERITAS;

- IGAS research;

- Alex Stewart International

- other independent certification firms.

The wire , rods, ingots are produced from:

- pure tantalum, tungsten, chromium, molybdenum - 99,0%, 99,6%; 99,9%; 99,99%; 99,999% (wt.%);

- tantalum, tungsten, chromium, molybdenum base alloys in accordance with GOST, ASTM, JIS , DIN and others,

Tantalum, tungsten, chromium, molybdenum:(brief information):

| Metal characteristic\ Metal | Tantalum | Tungsten | Chromium | Molybdenum |

| Atomic number | 73 | 74 | 24 | 42 |

| Density, g/cub.cm | 16.60 | 19.3 | 7.19 | 10,22 |

| Point of fusion , ° C | 3014 | 3380 | 1890 | 2622 |

| Temperature of ebullition , ° C | 5500 | 5900 | 2480 | 5960-5100 |

| Lattice structure | Body-centered cubic |

|||

| Surface colour | Grey -

steel,

bright |

Grey - steel | Grey -

steel,

bright |

Grey -

steel,

bright |

| Good chemical durability (20° C) in | Air, water, alkalies , acids, most of organic compounds | Air, water, alkalies , acids | Air, water.

It's lightly passivated |

Air, water, alkalies, some acids |

Now it is known more 5000 alloys with tantalum, tungsten, chromium, molybdenum content. Tantalum, tungsten, chromium, molybdenum and tantalum, tungsten, chromium, molybdenum base alloys are in want of special provision of melting, alloying , refinement and forming . Tantalum, tungsten, chromium, molybdenum wire and tantalum, tungsten, chromium, molybdenum base alloy wire, rods, ingots are used in chemical , aerospace, automobile, petrochemical industries , medicine, orthodontia, mechanical engineering, electronics, shipbuilding and etc.